Main Home page 로 이동 바랍니다 www.aeft.co.kr

자동차/가정용/산업용 에어컨 실험장치 및 계측기

3. Compressor Calorimeter System

4. Eva/Heater Calorimeter System

5. Condenser Calorimeter System

6. Automotive A/C System Calorimeter

8. Belt Tension Durability Test stand

9. A/C System Durability Test Stand

10. Compressor Durability Test stand

11. Radiator Durability Tester

특징

특징

-. Tunnel 제질이 투명 아크릴 이어서 관찰이 이

합니다.

-. ANSI Multi Nozzle 사용으로 저유량에서부터 많은

유량까지 측정할수 있습니다.

-. Fan, Blower의 크기, 용량 등에 따라 사양이 변경

됩니다.

_. 특징

승용차용 Fan, Blower, 및 산업용 중소형Fan, Blower 의 풍량

및 Dynamo를 측정할수 있습니다.

실험용 시료의 종류나 형태에 따라서 설계되어 집니다.

특징

자동차용 A/C system 의 풍량을 측정 합니다.

측정범위 : 4-150CFM

Power: 12V, 15A

Accurac : ±2%

3. Compressor Calorimeter System

Manufactures refrigerant compressor calorimeters for both the Automotive and HVAC industries. Our compressor calorimeters utilize the Secondary Refrigerant Method with Mass Flow Confirmation as described in ASHRAE Standards 23 and 41.9. AEFT utilizes a Micro Motion Coriolis mass flow sensor to provide accurate and repeatable determination of compressor capacity. Tescor's calorimeter system provides the customer with control of such parameters as compressor speed, discharge pressure, sub-cool temperature, suction temperature, and suction pressure. In addition, Tescor has developed an oil control loop that allows the user to precisely and accurately control and report the percentage of oil in circulation automatically. Our Hermetic Compressor Calorimeters can be provided with systems that measure the speed of the compressor as well as the winding resistance. The calorimeter systems are designed to provide heat balances within +/- 2% with a repeatability of +/-1%.

4. Eva/Heater Calorimeter System.

5. Condenser Calorimeter System

specification

Dry bulb temperature : 30 to 60℃

Dewpoint range : 5 to 32

Air Flow Range : 300 to 6000 CMH

Pressure Drop : 20mm Aq

Capacity condenser : 1000 to 15000 Kcal/Hr

Condenser Inlet pressure : 12 to 32 kg/Cm2

Condenser Inlet Temperature : 50 to 150℃

Mass Flow Measurement : 0 to 700 kg/Hr

6. Automotive A/C System Calorimeter

Specification

본장비는 차량용 A/C system 모두를 Test 할수 있습니다.

Condenser Room과 Heater/Eva. Room 두 개의 Room 으로 구성되어 있습니다

Compressure 는 Chamber 형식으로 설치됩니다.

상세 사양은 Test 할 시료의 capacity 에 따라 변경 됩니다.

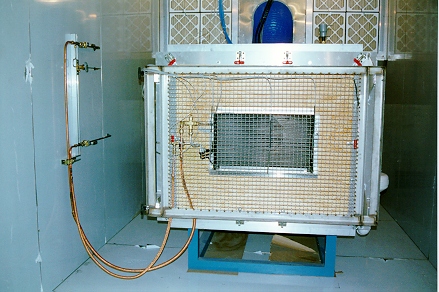

본장비는 가정용 Package Airconditioner 등을 Test 하는 장비로서 실내기(Eva. Side) 와 실외기 Condenser side 의 2개의 room 으로 구성되어 있으며 사용할 시료에 따라서 상세 사양이 결정되어 집니다.

8. Belt Tension Durability Test stand

본 장비는 자동차 구동장치에 사용되는 각종 Belt의 장력과 내구성을

시험하기 위한 장비입니다.

9. A/C System Durability Test Stand

10. Compressor Durability Test Stand

본 장치는 자동차용 Air Condition System을 자동차 엔진 회전수에 따라 최고 6000rpm 까지

주행 모드를 바꾸어 가면서 실험할수 있고

A/C 스위치의 반복작용 및 냉매량이 많고 적음에 따른 현상등

여러 각도에서 실험할수 있는 기초 장비임

Radiator에 Hot/Cool Water를

일정압으로 반복해서 가하므로서 시료가 가지고 있는 내구성과 성능을 평가 하기 위한 장비입니다.

AEFT 엡트텍

e-mail

: airforce71@yahoo.co.kr

homepage : www.aeft.co.kr